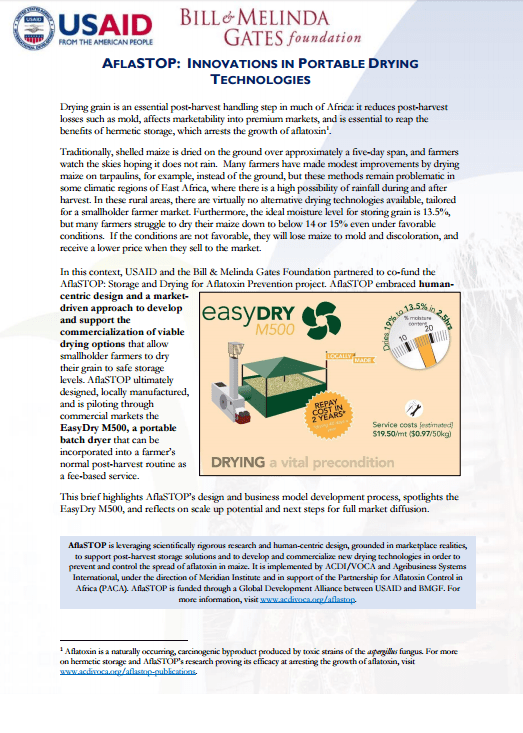

Drying grain is an essential post-harvest handling step in much of Africa: it reduces post-harvest losses due to mold, affects marketability into premium markets, and is essential to reap the benefits of hermetic storage, which arrests the growth of aflatoxin. In this context, the AflaSTOP project embraced human-centric design and a market-driven approach to develop and support the commercialization of viable drying technologies that allow smallholder farmers to dry their grain to safe storage levels. AflaSTOP ultimately designed, locally manufactured, and is piloting through commercial markets the EasyDry M500, a portable batch dryer that can be incorporated into a farmer’s normal post-harvest routine as a fee-based service.

This brief highlights AflaSTOP’s design and business model development process, spotlights the EasyDry M500, and reflects on scale up potential and next steps for full market diffusion.